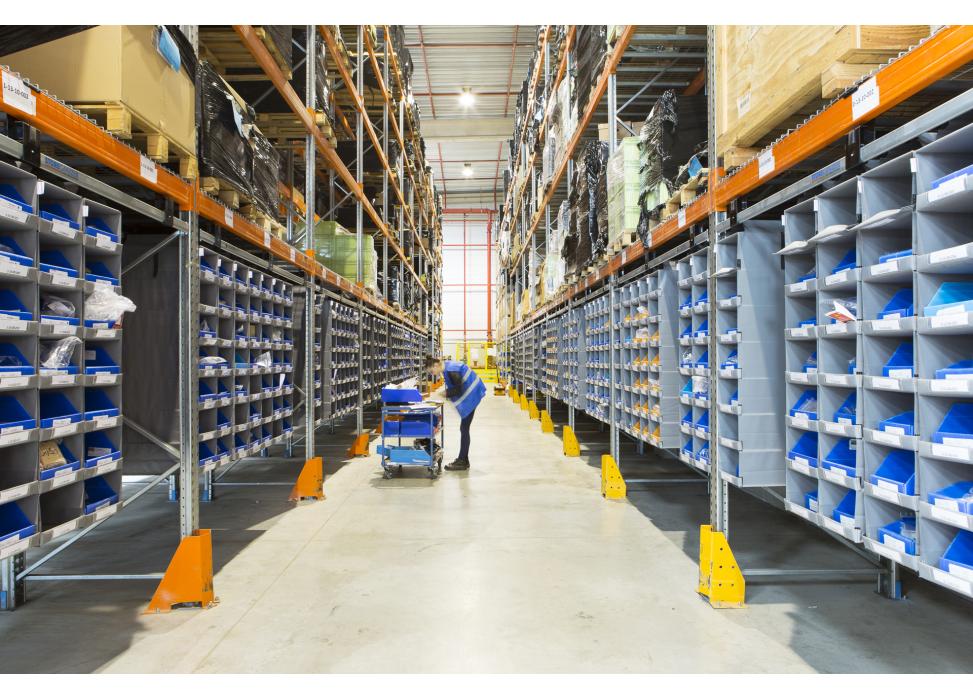

Compact shelving with tall, deep aisles for pallet storage. This system is ideal when there are many pallets with the same product, or to consolidate shipments.

THE IDEAL SOLUTION FOR THE DEEP STORAGE OF LOADS WITH THE SAME PRODUCT

Drive-in storage is a compact storage system. It is largely characterised by its great optimisation of storage space, making use of up to 85% of storage space available.

Its design means that we can make the most of the height and space of your warehouse by reducing working aisles. Direct access to each pallet is lost in exchange for an increase in useful space.

It can be adapted to needs according to the space, measurements, weight, and volume of merchandise. It is an ideal system for the storage of the same product the and periodic inward and outward movement of merchandise.

We offer two types of compact storage:

- Drive-in shelves: Loads enter through one end of the facility.

- Drive-through shelves: Loads enter through both ends of the facility. Both options can bear heavy loads, and are very robust and safe.

Benefitts: Drive In

Compact system - en

This type of installation consists of a series of aisles through which forklifts enter to deposit pallets on rails. These can be placed at different heights, depending on the storage needs of the client. The most significant characteristic of this storage system is its compression, which is conducive to productivity by optimising resources available.

Quality - en

For us, quality in all manufacturing processes is a priority.

Technology - en

The most flexible and advanced production systems for the design and manufacture of competitive parts, components, and metal products.

Logistical analysis of requirements - en

Our team has extensive logistics and handling experience. We will analyse your needs with you and provide the best possible solution.

Technical shelf audit - en

Our shelf audit technicians will propose the corrective interventions that the installations may require over time. The modular nature of the shelving system means that it is possible to replace only damaged components.

Benefits: Drive-in storage

Compact system

This type of installation consists of a series of aisles through which forklifts enter to deposit pallets on rails. These can be placed at different heights, depending on the storage needs of the client. The most significant characteristic of this storage system is its compression, which is conducive to productivity by optimising resources available.

Quality

For us, quality in all manufacturing processes is a priority.

Technology

The most flexible and advanced production systems for the design and manufacture of competitive parts, components, and metal products.

Logistical analysis of requirements

Our team has extensive logistics and handling experience. We will analyse your needs with you and provide the best possible solution.

Technical shelf audit

Our shelf audit technicians will propose the corrective interventions that the installations may require over time. The modular nature of the shelving system means that it is possible to replace only damaged components.

Other solutions for Racking & Shelving

Palletising

Designed for the palletised storage of products, with direct access to all locations

Medium load

A manual loading storage system for all types of merchandise and products. Based on the frame-and-crossbar concept and on palletising, although sized for the load capacities required.

CASTELLANO

CASTELLANO

.jpg)