Usually used for high-rotation products. Its resulting operation ensures FIFO. Available in Dinámica de Bulto and Dinámica de Palet.

GRAVITY-OPERATED, HIGH-DENSITY COMPACT STORAGE SYSTEM

For perfect product rotation, DYNAMIC storage systems are the best solution.

This shelving system, which has a support base consisting of rollers and pulleys, can be used both for PALLETISED loads (Dinámica de Palet) and for medium or light loads (Dinámica de Bulto).

Dinámica de Palet:

- The system for storing pallets on dynamic shelves is based on the same structure as a conventional compact shelf, but with levels on a slight incline vis-a-vis the floor, where the rollers on which merchandise is transported are.

- FIFO and LIFO system - Adaptable to any type of loading unit.

- Guarantees the continuous flow of materials.

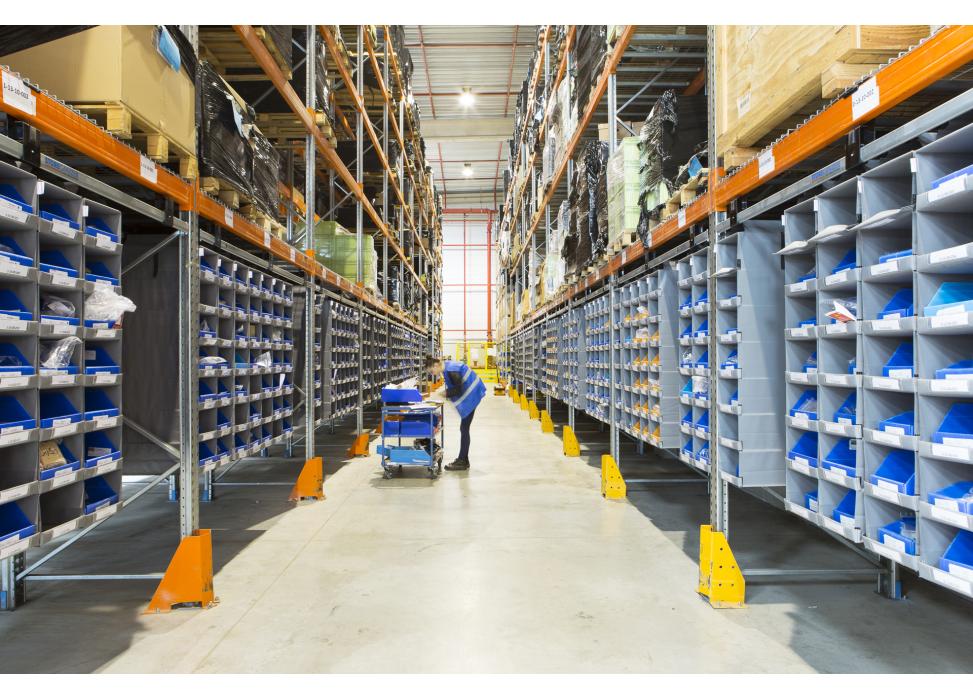

Dinámica de Bulto:

- Shelves comprised of inclined platforms with rollers or pulleys that optimise the entry and exit of material.

- FIFO (first in, first out)

- A large number of products at the front of the shelves.

- Reduction in order preparation time.

- The ability to implement PICK TO LIGHT systems to increase productivity without losing flexibility.

Benefitts: Dinámicas

Space savings - en

This roller-based compression system optimises the use of space in the warehouse.

Cost savings - en

Its optimisation of available space, the simplicity of its operation, and the limited maintenance required, as well as the reduction in time required for loading and unloading operations, mean that the investment required to implement the dynamic shelving system pays for itself within a short time, offering a high return on the investment.

Increase in productivity - en

Loading via one end and unloading via the other guarantees the continuous flow of the product, since both operations can be carried out at the same time.

Versatility - en

Can be adapted to the needs of the client. Compatible with other storage systems.

Security - en

Given that forklifts do not have to enter the aisles, the risk of accidents is virtually non-existent and there is no damage to the structure of the shelves.

Technical shelf audit - en

Our shelf audit technicians will propose the corrective interventions that the installations may require over time. The modular nature of the shelving system means that it is possible to replace only damaged components.

Benefits: Dynamics

Space savings

This roller-based compression system optimises the use of space in the warehouse.

Cost savings

Its optimisation of available space, the simplicity of its operation, and the limited maintenance required, as well as the reduction in time required for loading and unloading operations, mean that the investment required to implement the dynamic shelving system pays for itself within a short time, offering a high return on the investment.

Increase in productivity

Loading via one end and unloading via the other guarantees the continuous flow of the product, since both operations can be carried out at the same time.

Versatility

Can be adapted to the needs of the client. Compatible with other storage systems.

Security

Given that forklifts do not have to enter the aisles, the risk of accidents is virtually non-existent and there is no damage to the structure of the shelves.

Technical shelf audit

Our shelf audit technicians will propose the corrective interventions that the installations may require over time. The modular nature of the shelving system means that it is possible to replace only damaged components.

Other solutions for Racking & Shelving

Palletising

Designed for the palletised storage of products, with direct access to all locations

Drive-in storage

Compact shelving with tall, deep aisles for pallet storage. This system is ideal when there are many pallets with the same product, or to consolidate shipments.

Medium load

A manual loading storage system for all types of merchandise and products. Based on the frame-and-crossbar concept and on palletising, although sized for the load capacities required.

CASTELLANO

CASTELLANO

.jpg)